Plug and PlAAS

- Category: Digital Twins, IoT

- Employer: FH Aachen IAAM

- Project date: 2023

Project Information

Plug and PlAAS

"Plug and PlAAS" is a project I developed during my research tenure at the FH Aachen Institute for Applied Automation and Mechatronics under the guidance of Prof. Wollert.

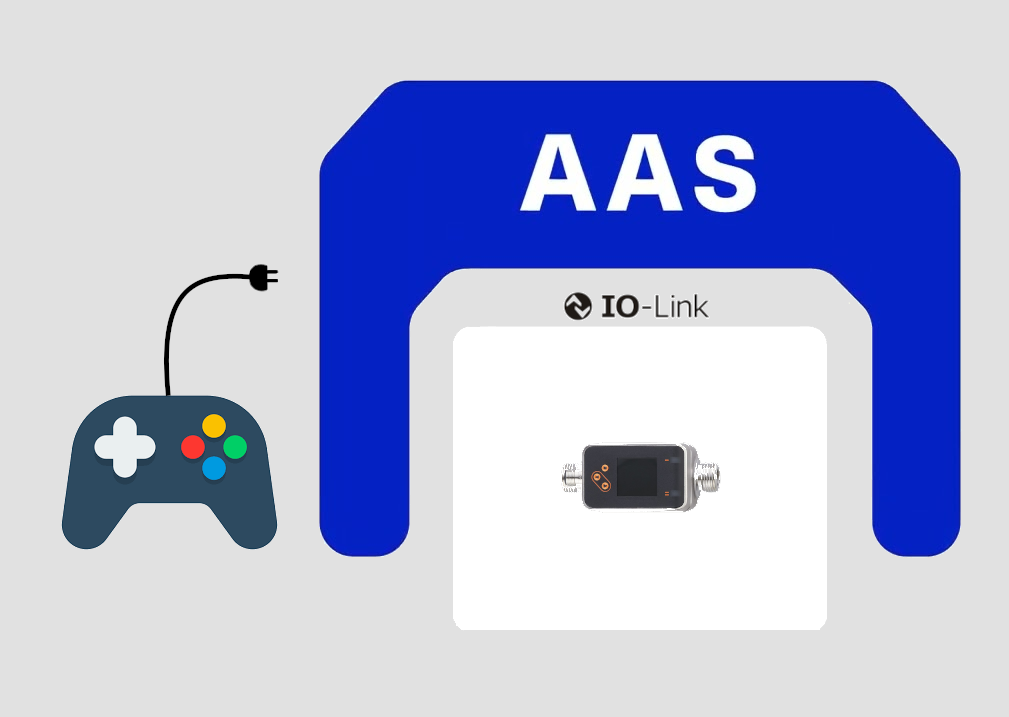

The primary objective of the project was to dynamically generate Asset Administration Shells (AASs) using device metadata sourced from existing profiles, particularly those utilized with IO-Link devices. The system has the capability to generate Nameplate submodels and Operational Data submodels for any sensor connected to an IO-Link master. It promptly deploys the newly created AAS to a server and furnishes it with dynamic data sourced from the sensor. As long as the system maintains an internet connection, it can retrieve IODD (IO Device Description) information online, enabling it to generate a tailored AAS specific to each sensor, including its individual serial number, software revisions, etc. When a sensor is disconnected from the system, the operational data is updated to reflect the absence of connection to the device. Upon reconnecting a known device to the IO-Link master, there's no need to generate a new AAS; the system automatically re-establishes the connection to the existing AAS. These capabilities render the system unique at the time of writing. A significant amount of effort was invested in ensuring the system's flexibility, which was needed if it was to have such a fitting name.

Furthermore, this project served as the foundation for a paper titled "Automatic Generation and Orchestration of Active Asset Administration Shells with IO-Link," which I presented at the "Kommunikation in der Automation" conference in Magdeburg, Germany, in November 2023.

The open-access paper is available at http://dx.doi.org/10.25673/111743 for those interested in delving into the technical intricacies of the project.

The video below demonstrates the plug-and-play capabilities of the system using an individual IO-Link master with a single sensor. Additionally, the system has been tested extensively with the much larger testbed depicted in the images above.

Although I developed this project myself, many things would have proven much more difficult without the support of Victor Chavez, Sebastian Braun, and Prof. Wollert in their respective areas.